Beacon Machine Diesel Test Bench Software System | Features, Database & FAQ

Unlocking Precision: Inside the Beacon Machine Diesel Test Bench Software System

Introduction

The heart of any high-quality diesel test bench is not just the motor or the rail—it’s the software that controls them. The Beacon Machine Diesel Test Bench Software System is designed to provide diesel workshops with OE-level precision, massive data coverage, and user-friendly operation.

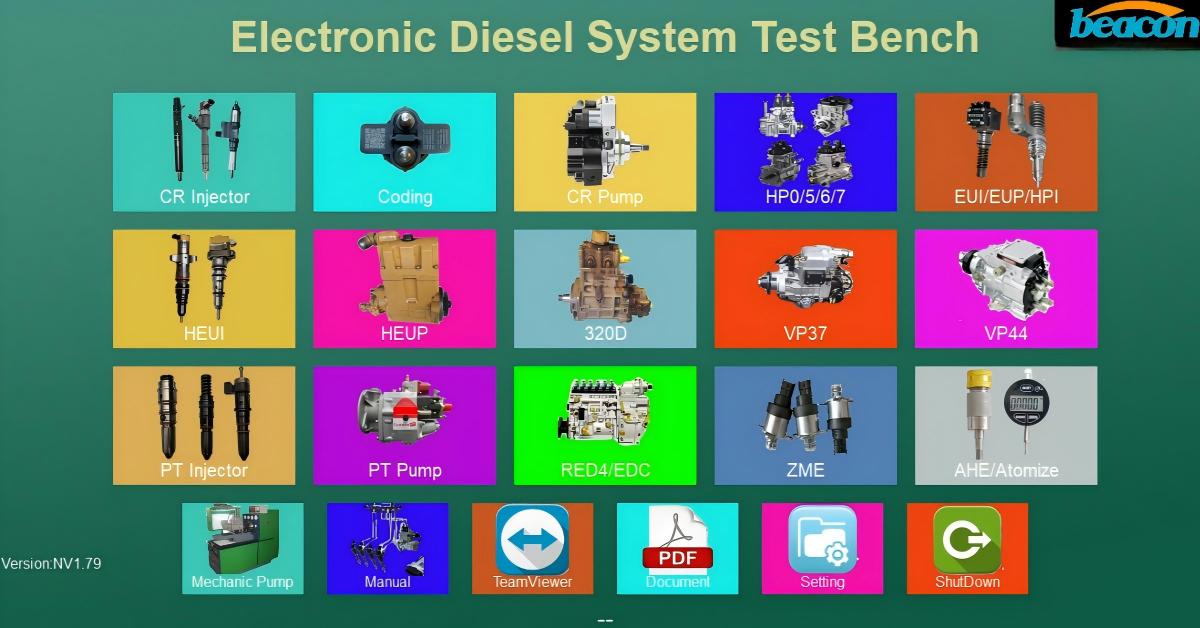

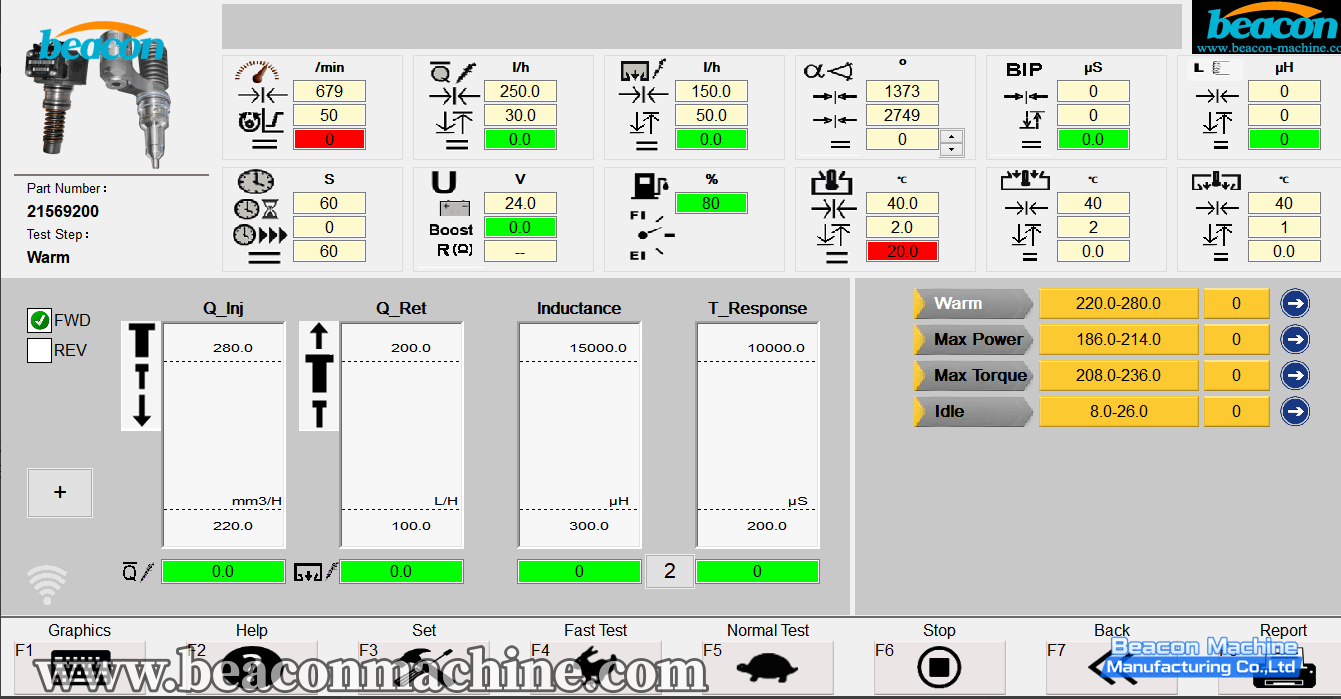

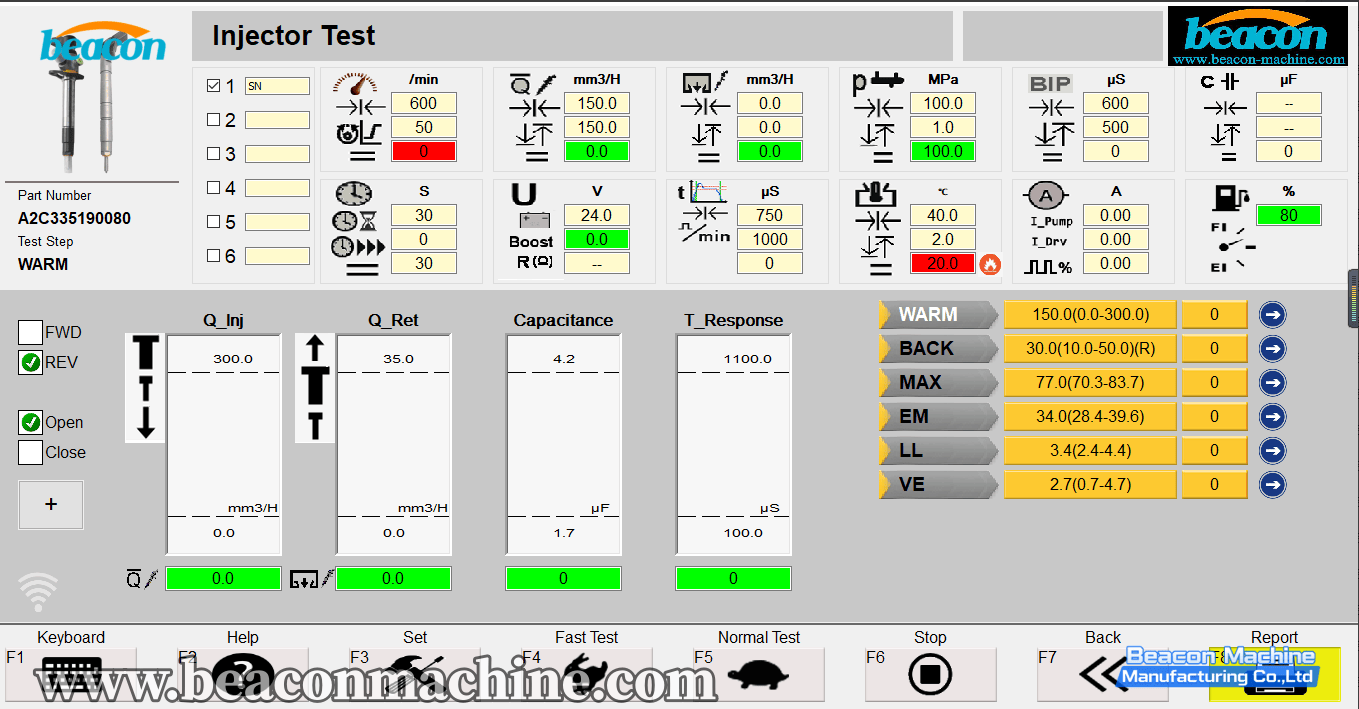

1. Comprehensive Testing Capabilities

The software is engineered to handle a vast array of diesel components. It supports Bosch, Delphi, Denso, Siemens, Caterpillar, and Cummins systems.

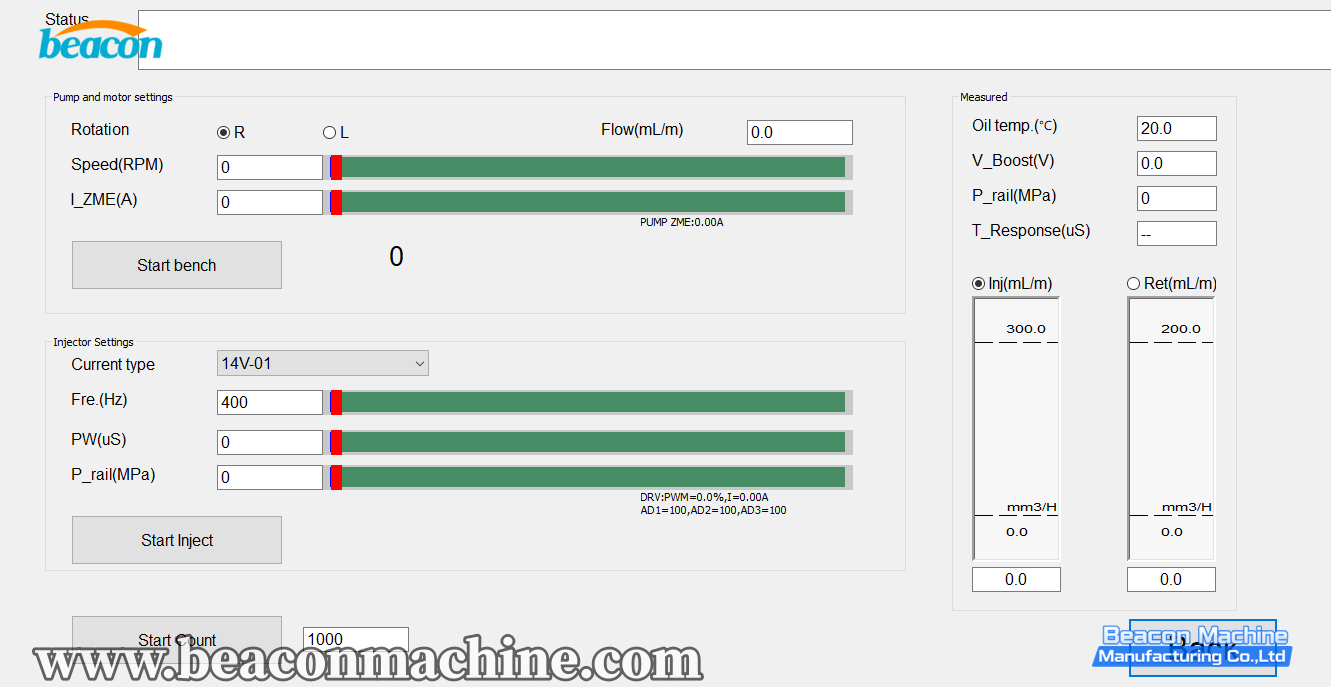

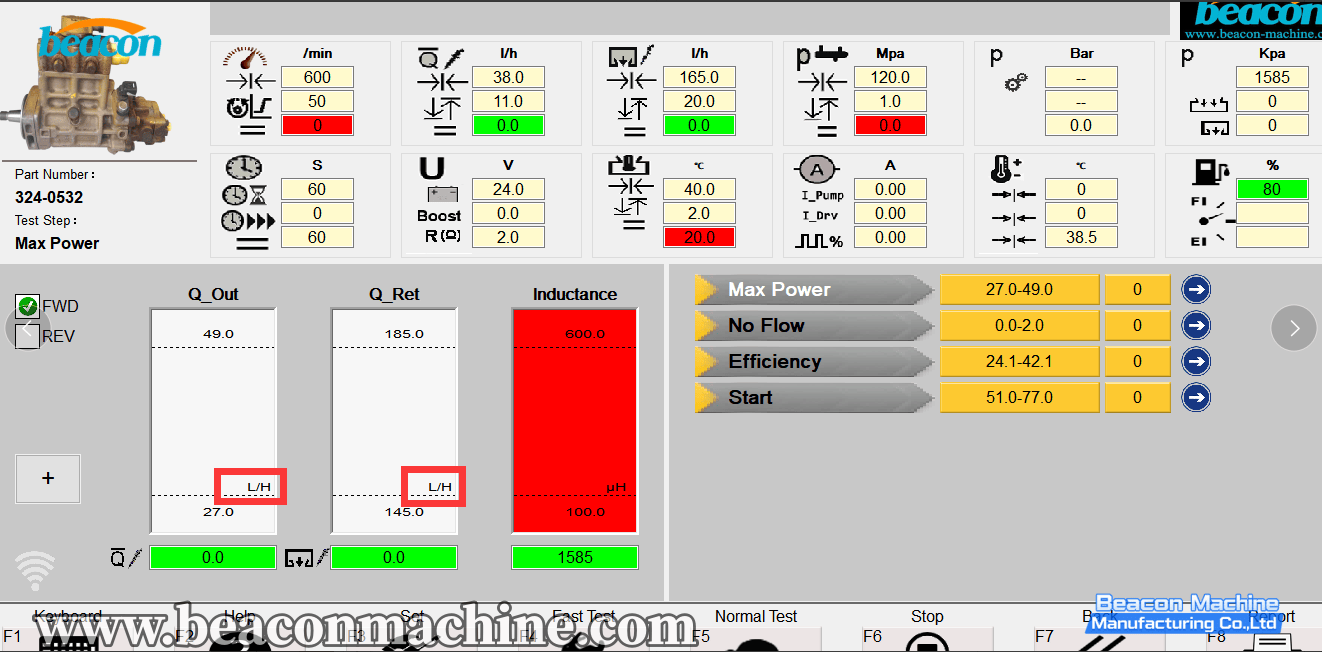

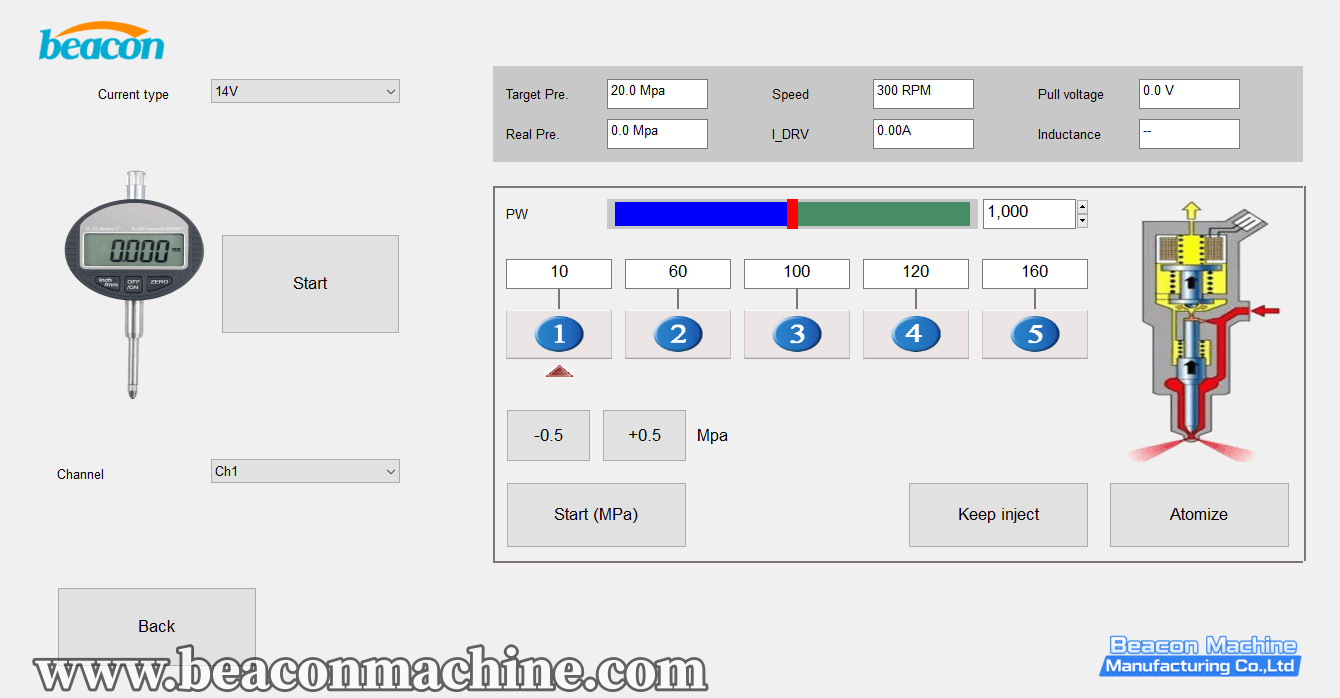

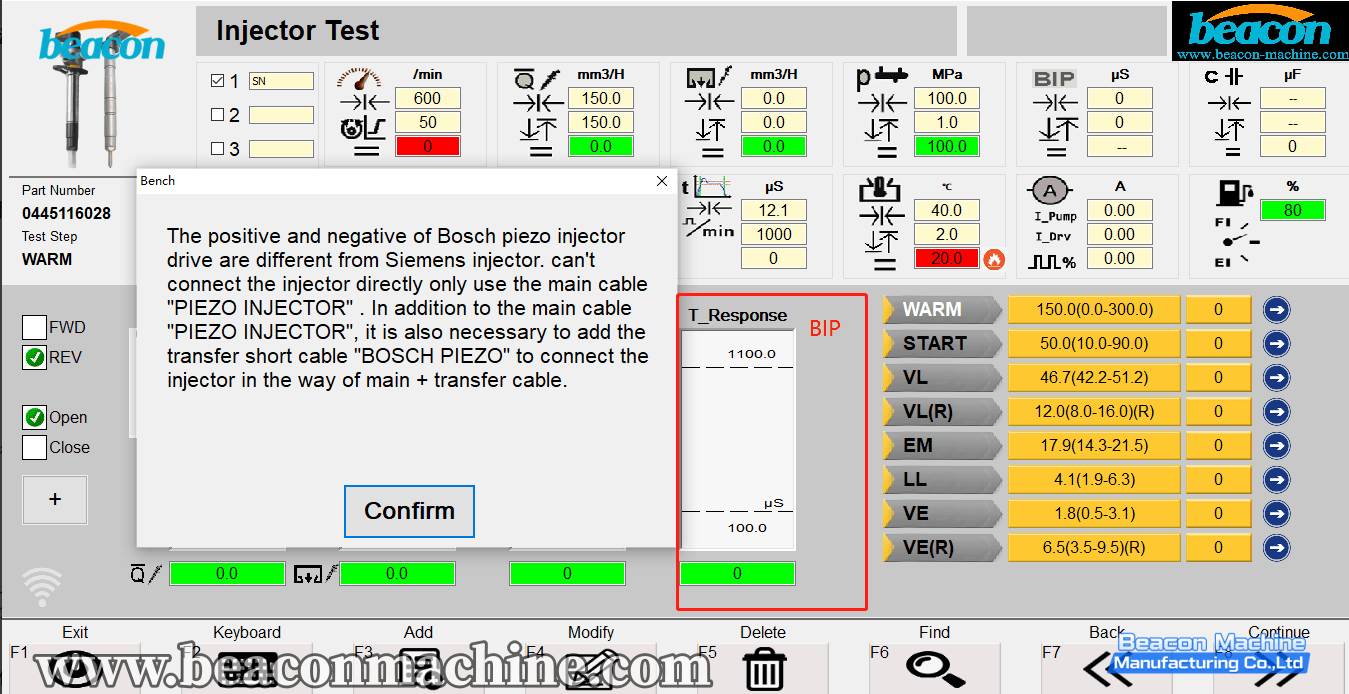

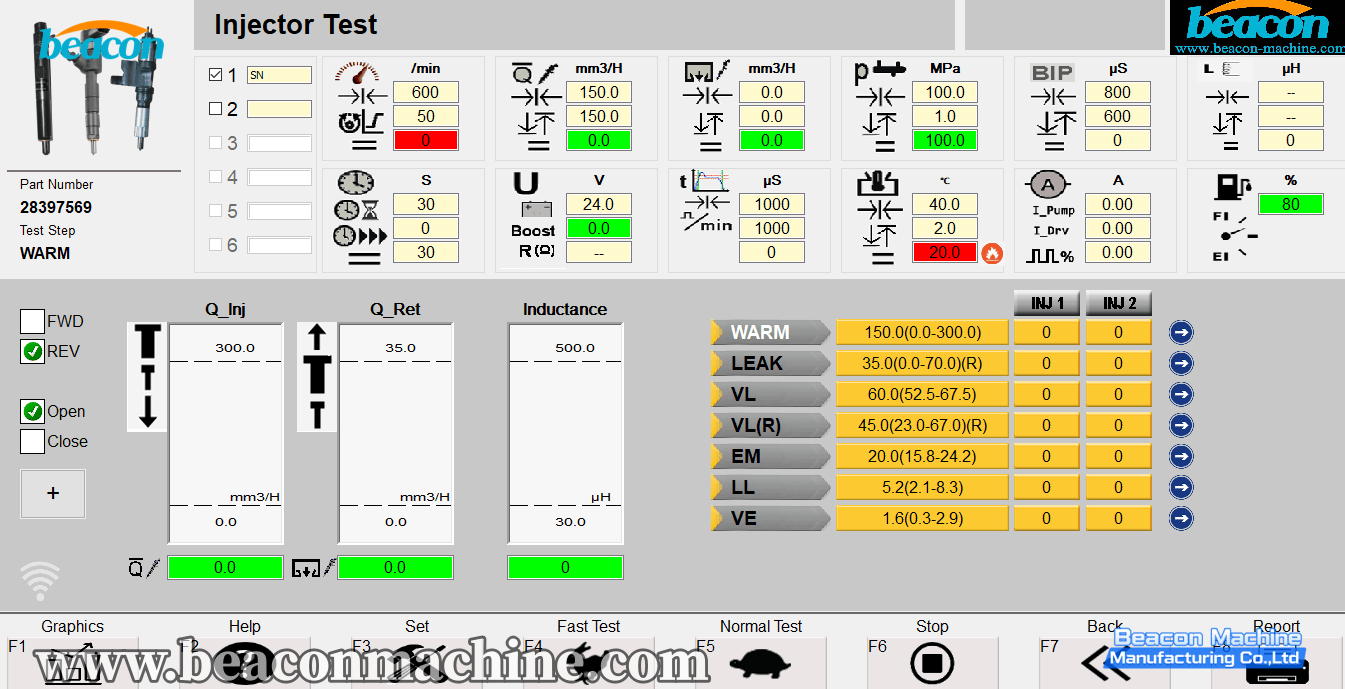

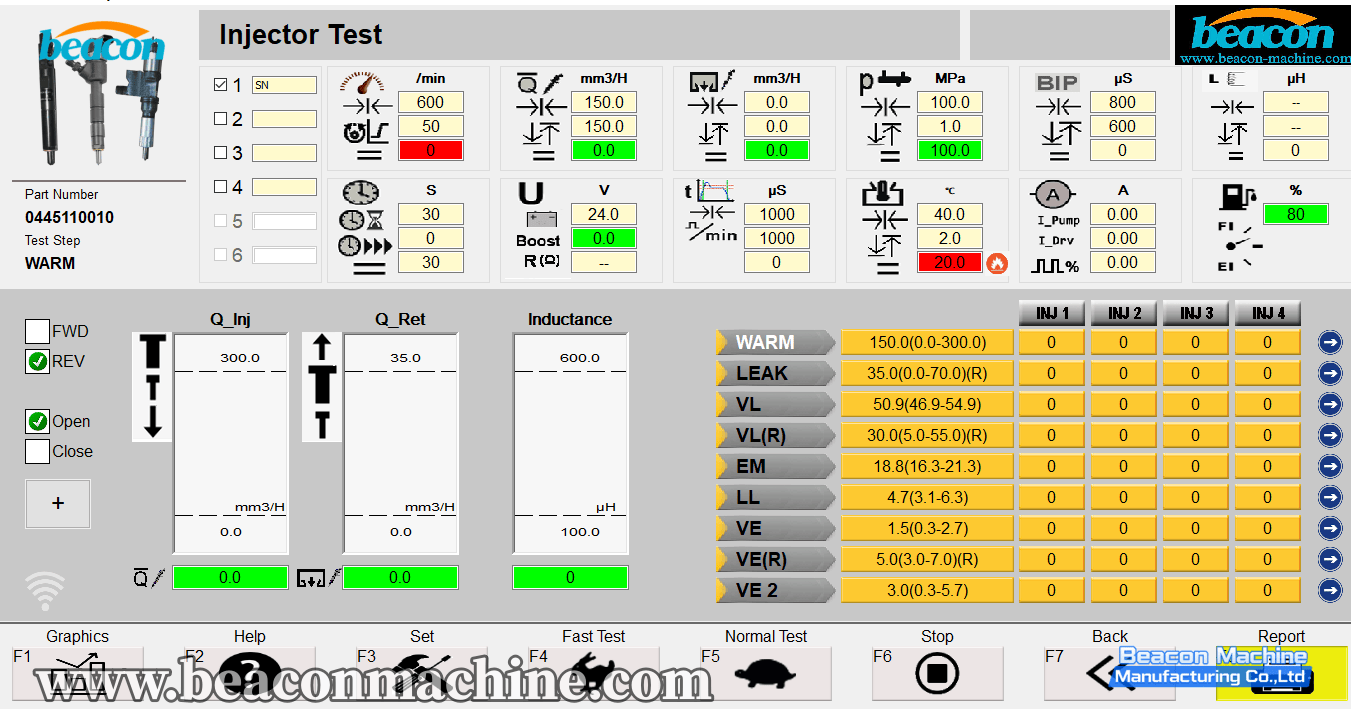

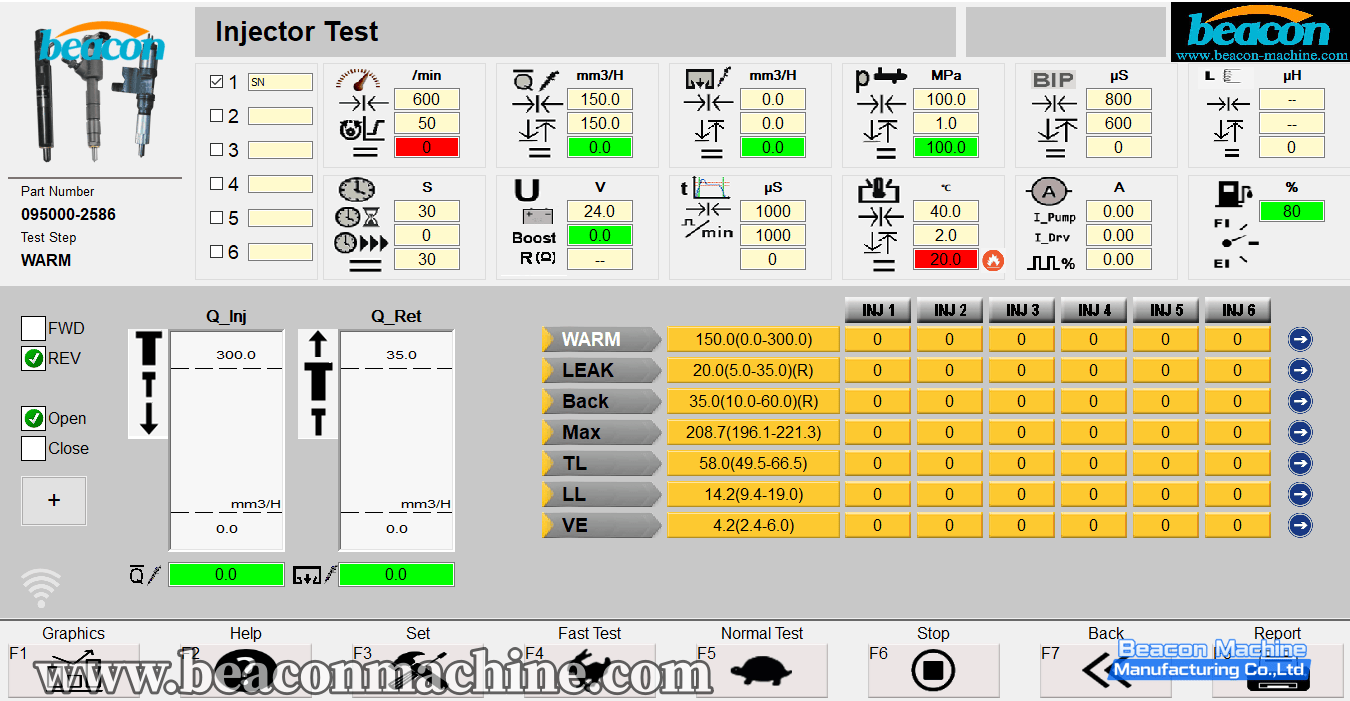

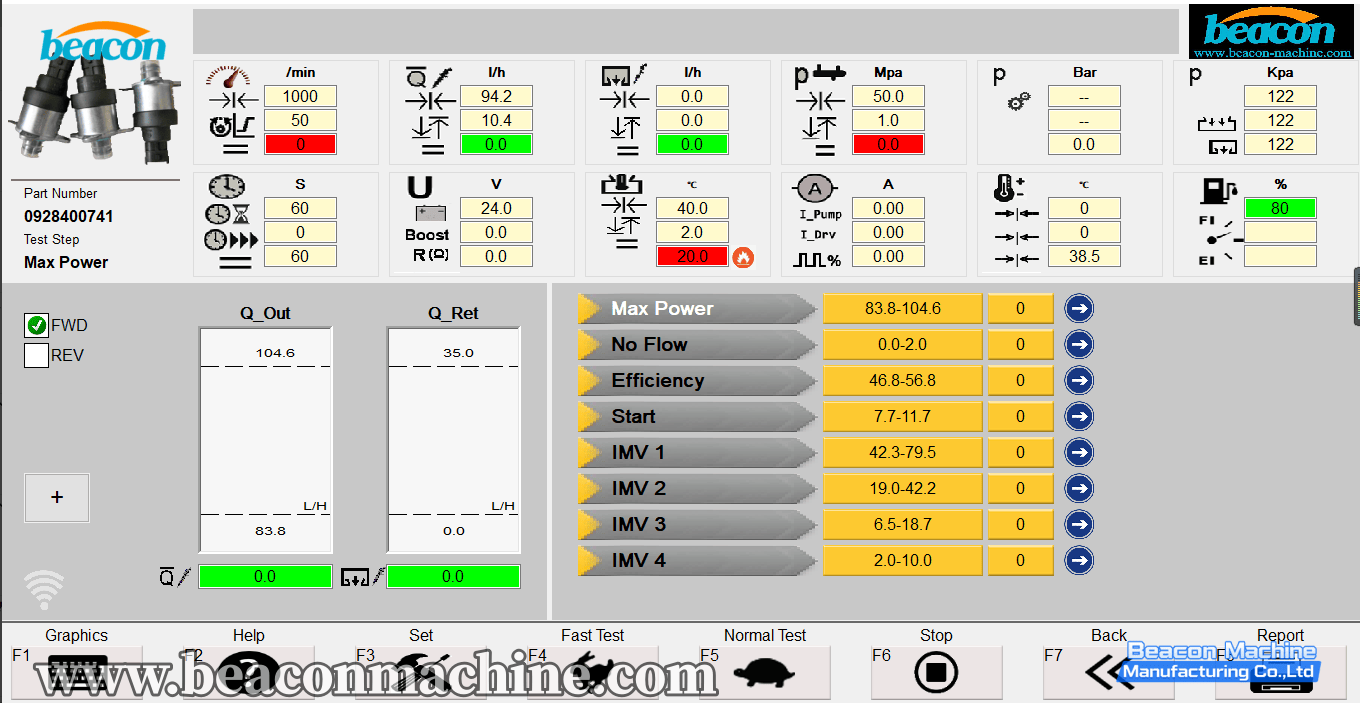

Common Rail Injectors & Pumps: Fully supports solenoid and piezo injectors, plus pumps equipped with ZME metering units (including CP4 and Denso SCV).

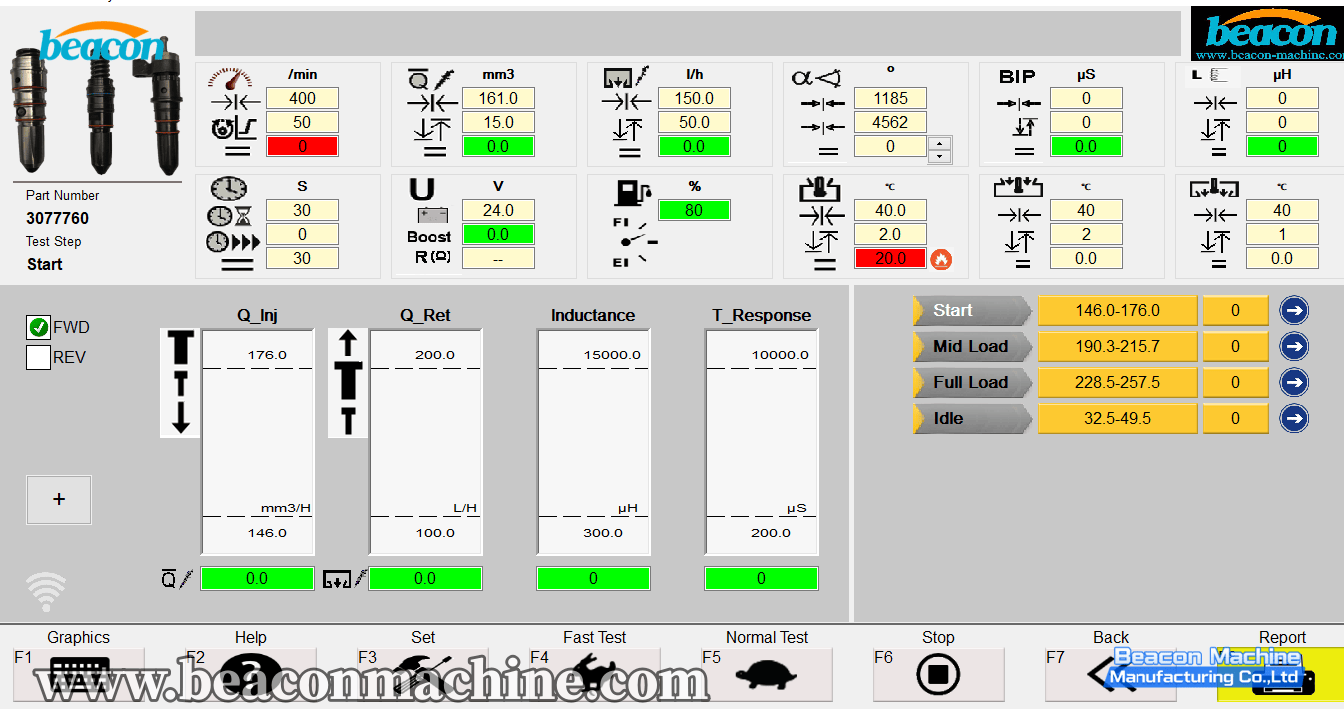

EUI/EUP Systems: capable of testing Bosch, CAT, Cummins, and Delphi EUI/EUP. This includes advanced support for Delphi E3 double solenoid and Cummins M11 double pulsing EUI.

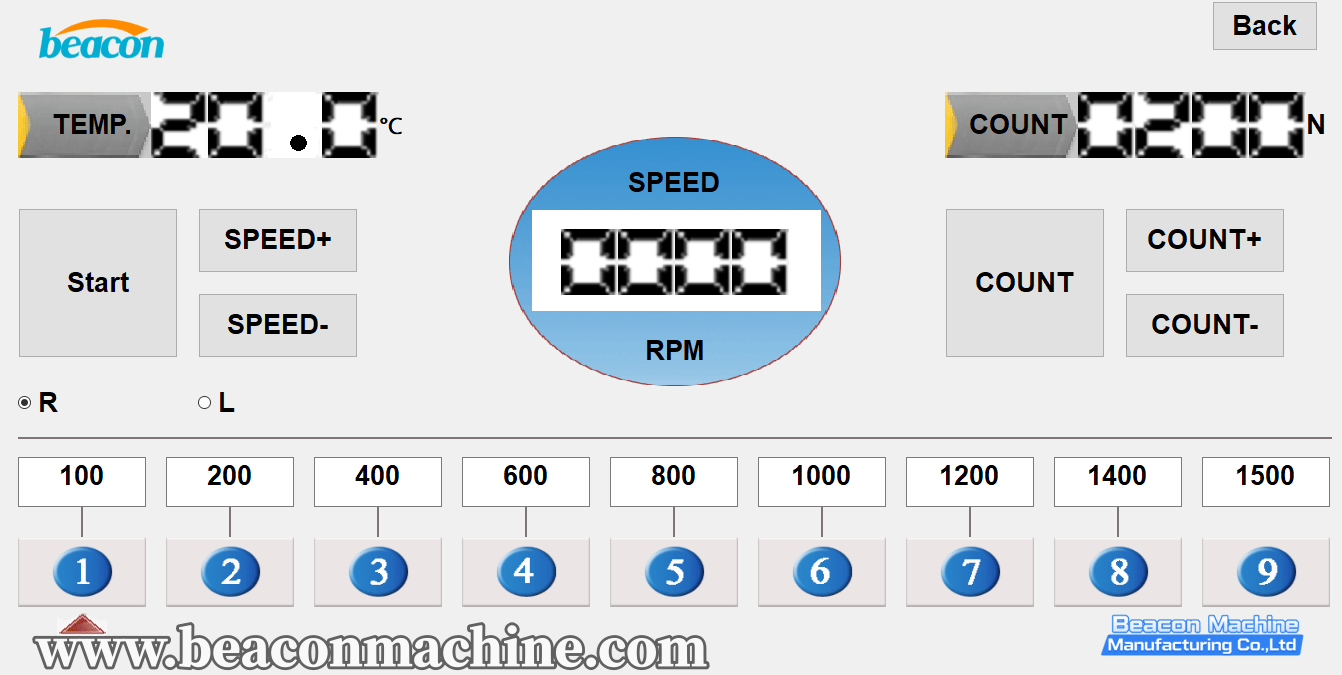

Heavy Duty Systems: Optional modules allow for testing HEUI injectors and pumps, as well as the Caterpillar 320D pump.

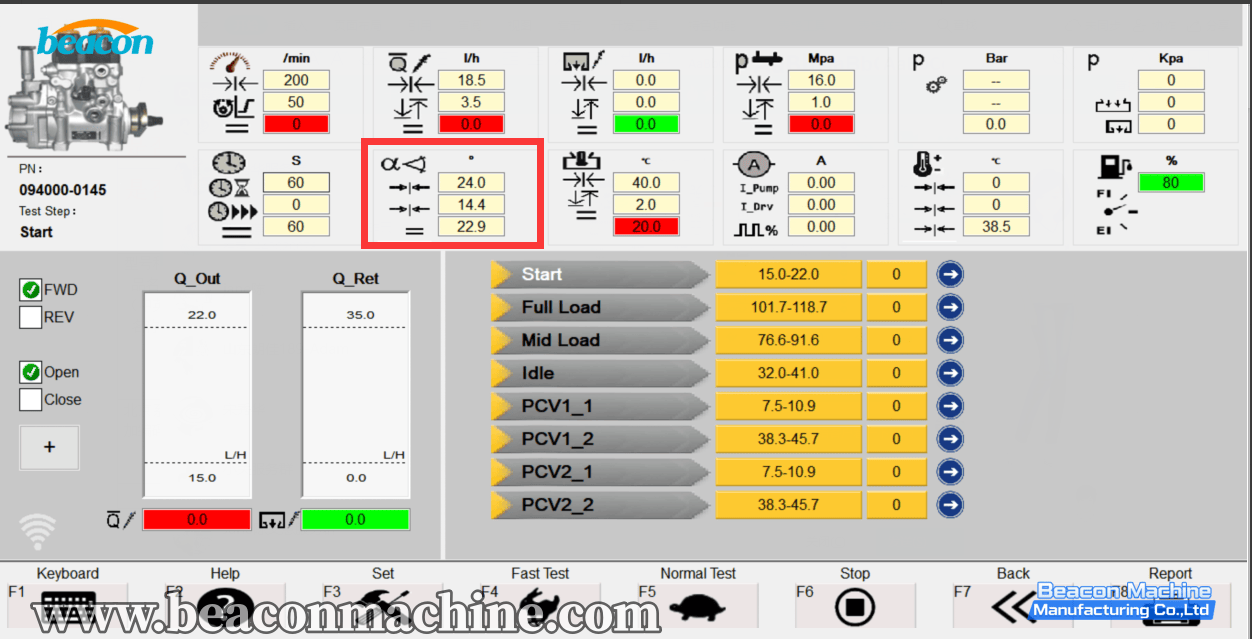

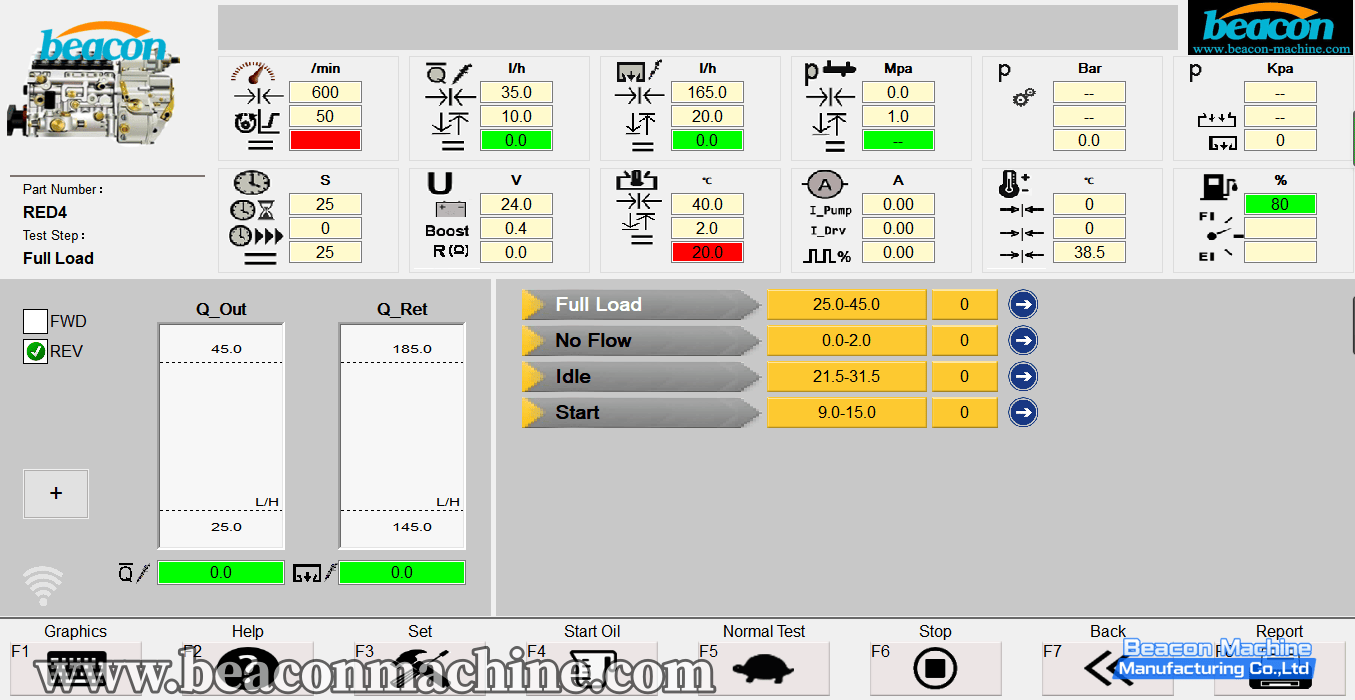

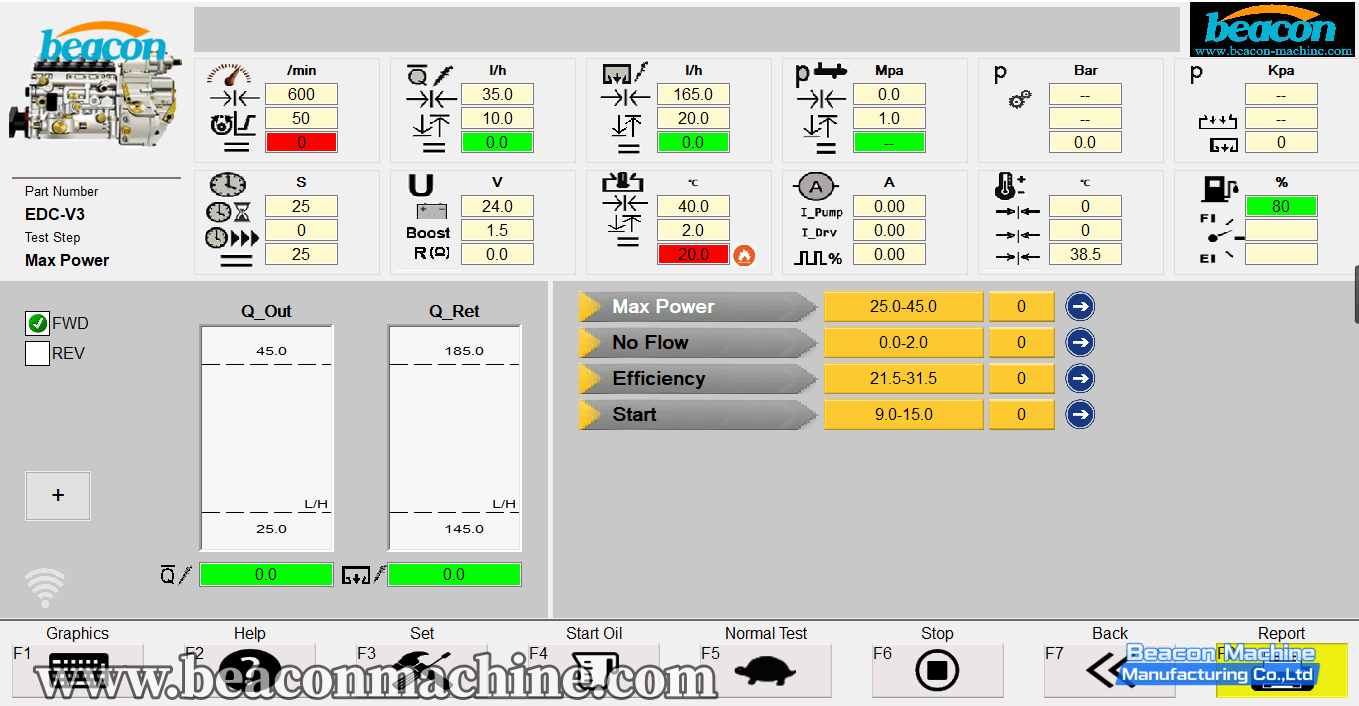

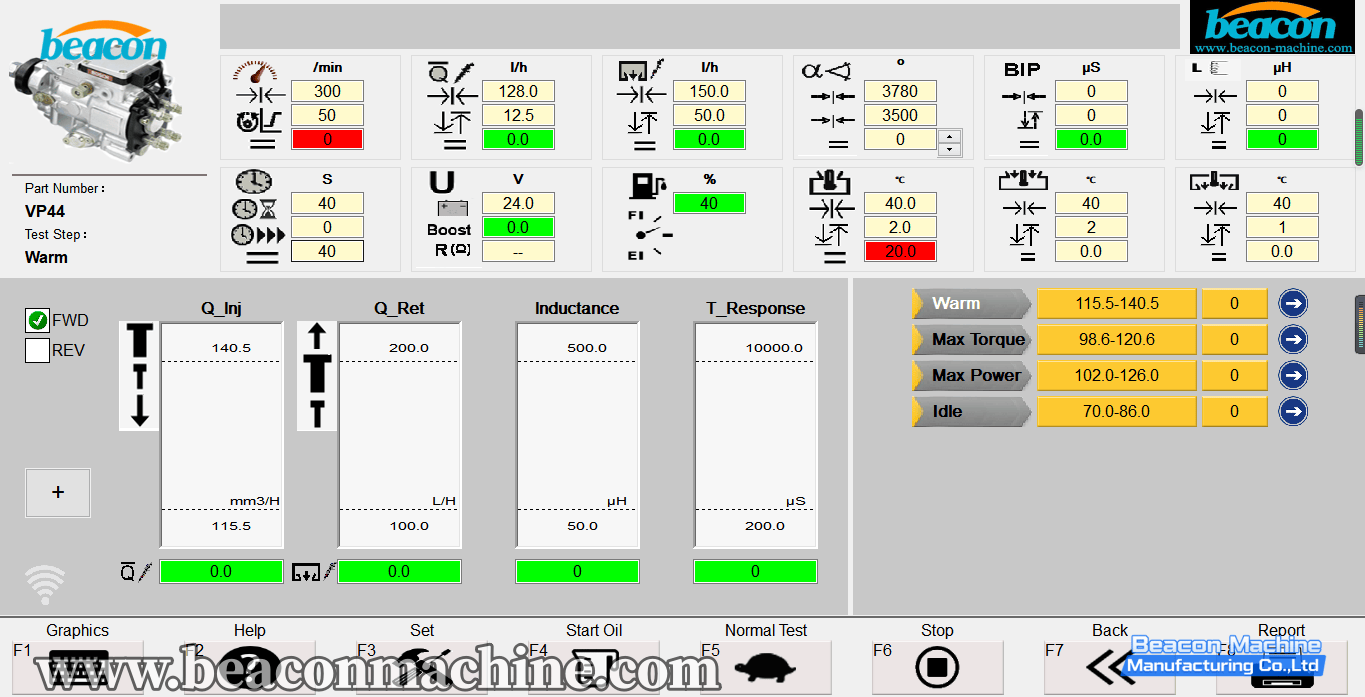

Traditional & Distributor Pumps: Covers VP37, VP44, RED4, and Denso V3/V4/V5 pumps.

Cummins Specialty: Supports HPI injectors, PT pumps, and XPI (ISX/X15) systems.

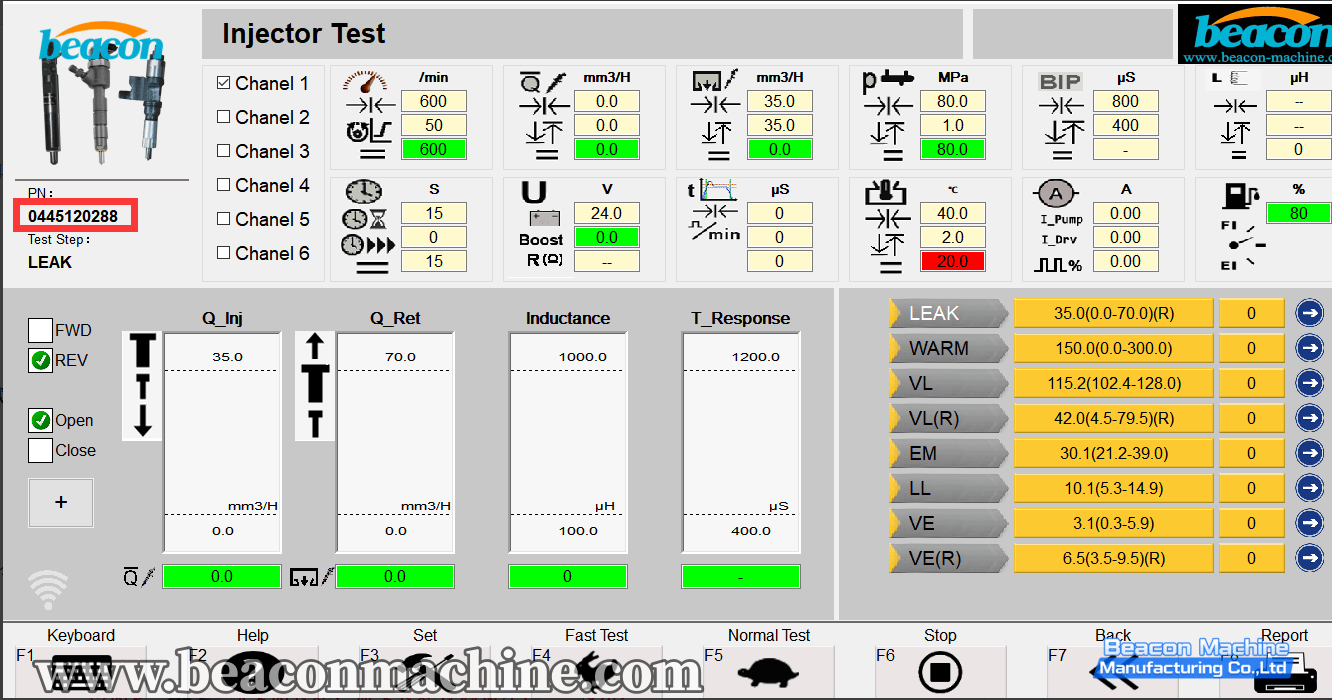

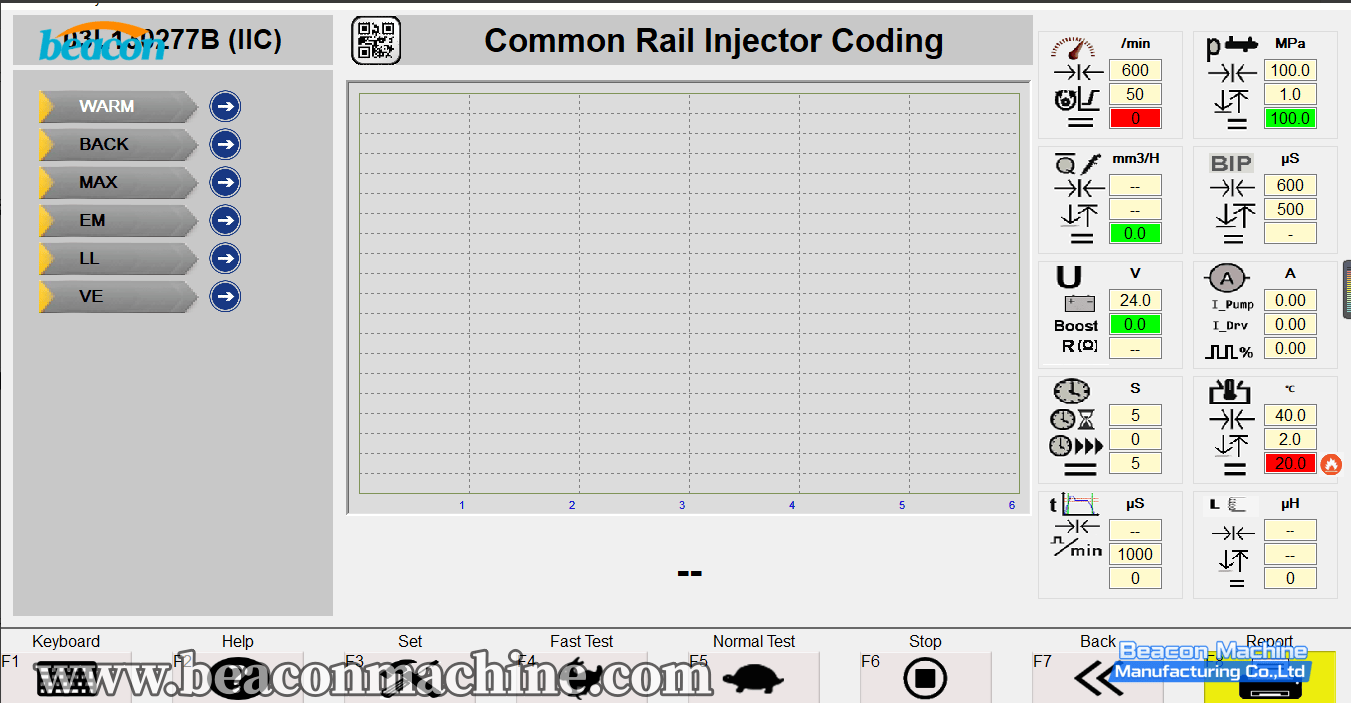

2. Advanced Injector Coding

Modern repair is impossible without coding. The Beacon Machine software generates codes that match original factory standards, ensuring the ECU can balance the engine correctly.

Bosch: IQA / IMA / ISA

Denso: QR Codes (16/22/24/26/28/30/32 digits)

Delphi: I2C / I3C

Siemens: IIC

Cummins: XPI (Optional)

3. The Power of Data: Extensive Database

The system comes pre-loaded with a massive database that is consistent with original data.

Common Rail Injectors:7,725 test plans (including 2,587 Bosch, 4,287 Denso, 171 Siemens, 449 Delphi).

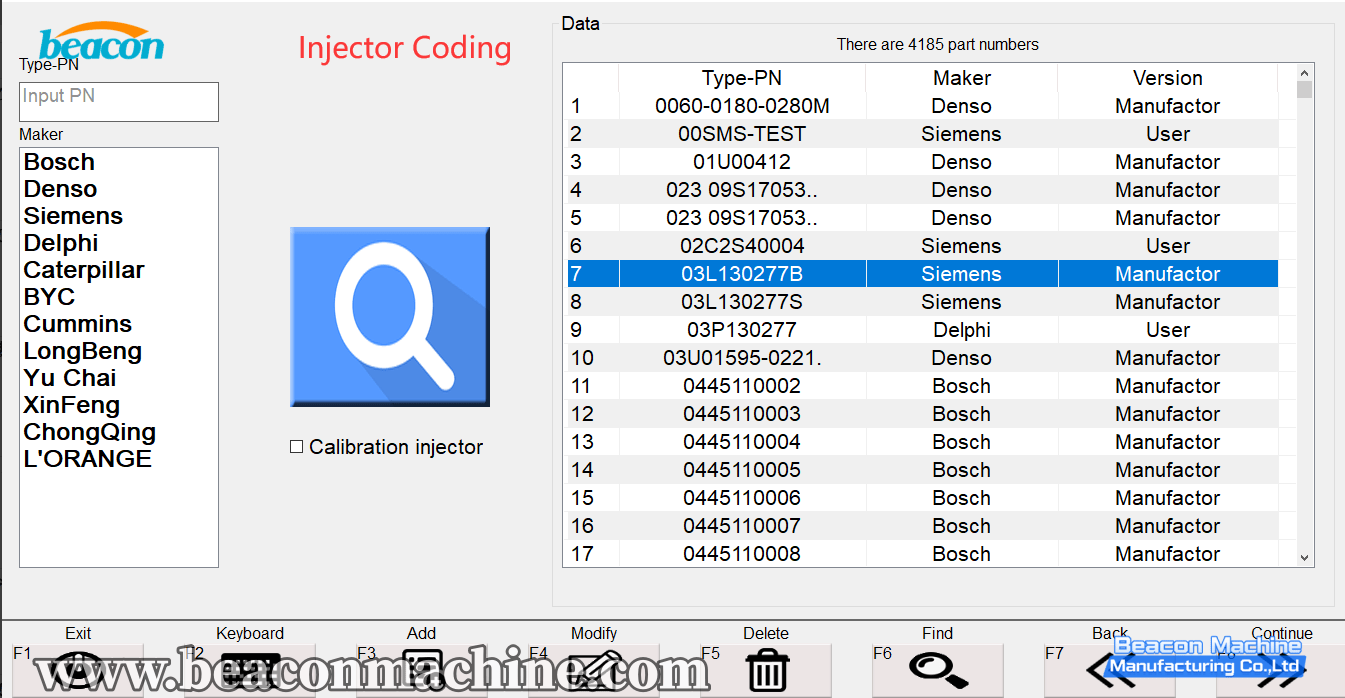

Coding Data:4,185 built-in coding plans.

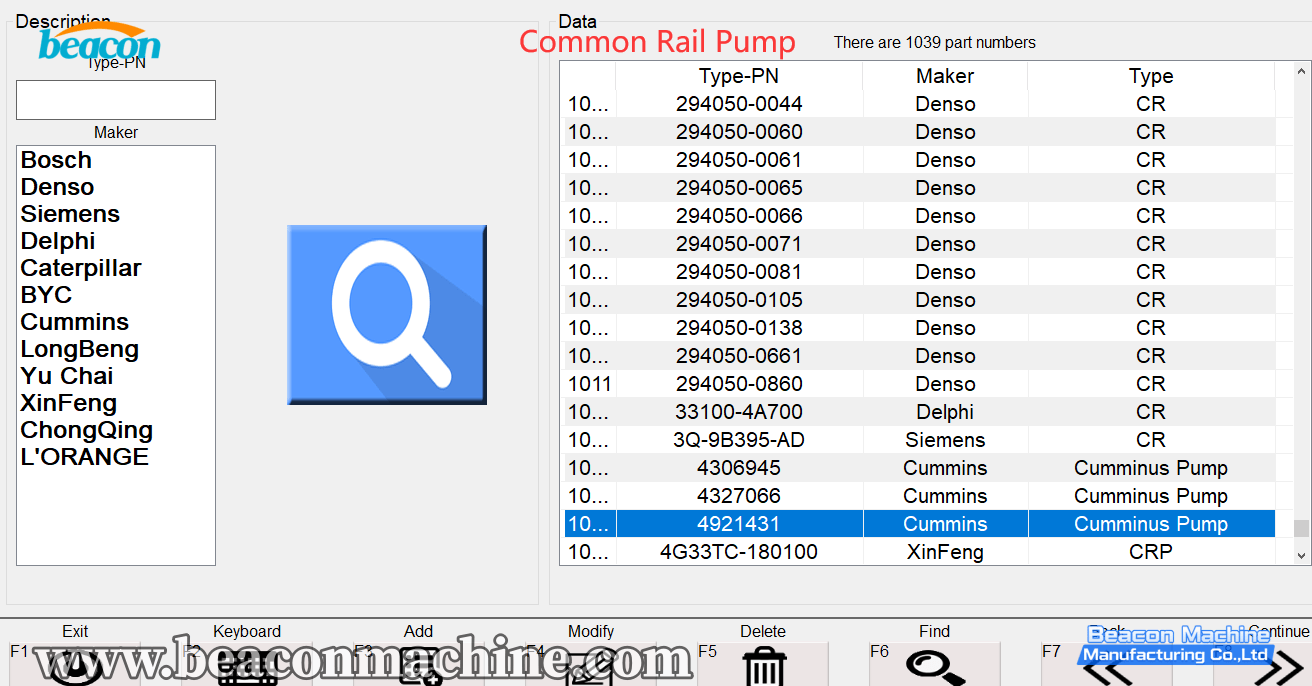

Common Rail Pumps:1,821 test plans.

Other Systems:

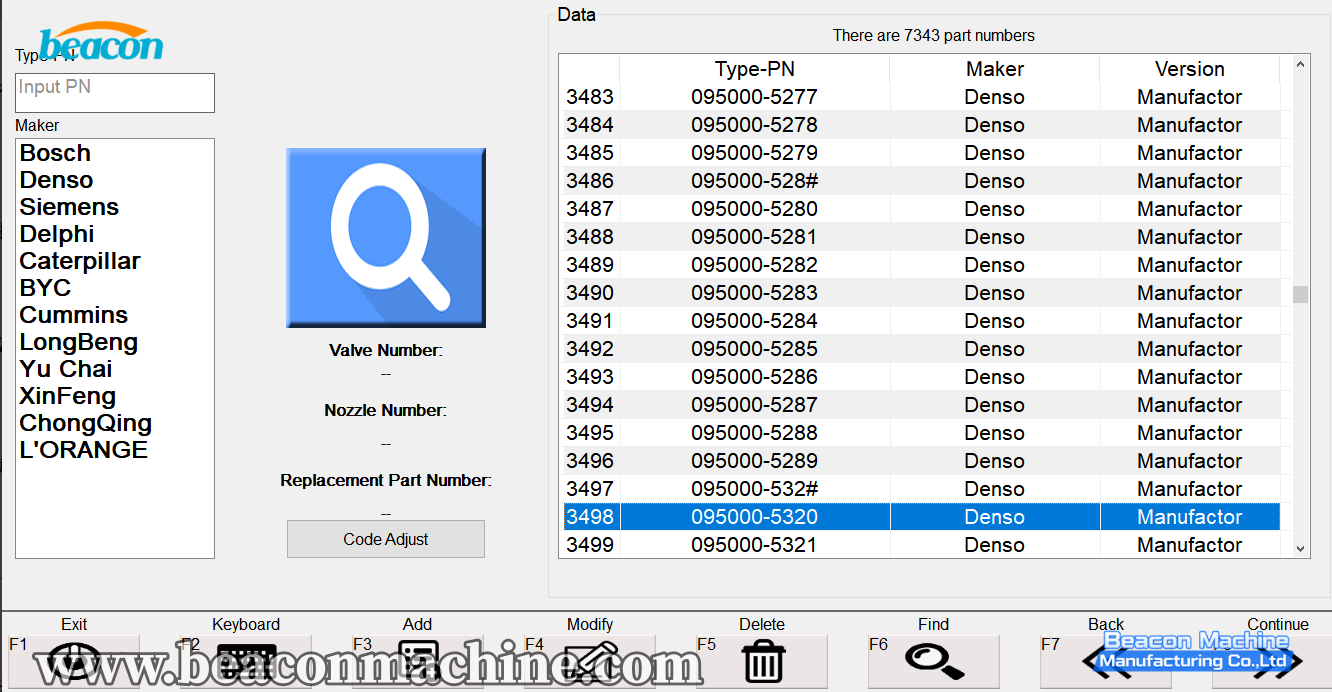

AHE (Armature Lift): 7,343 data points.

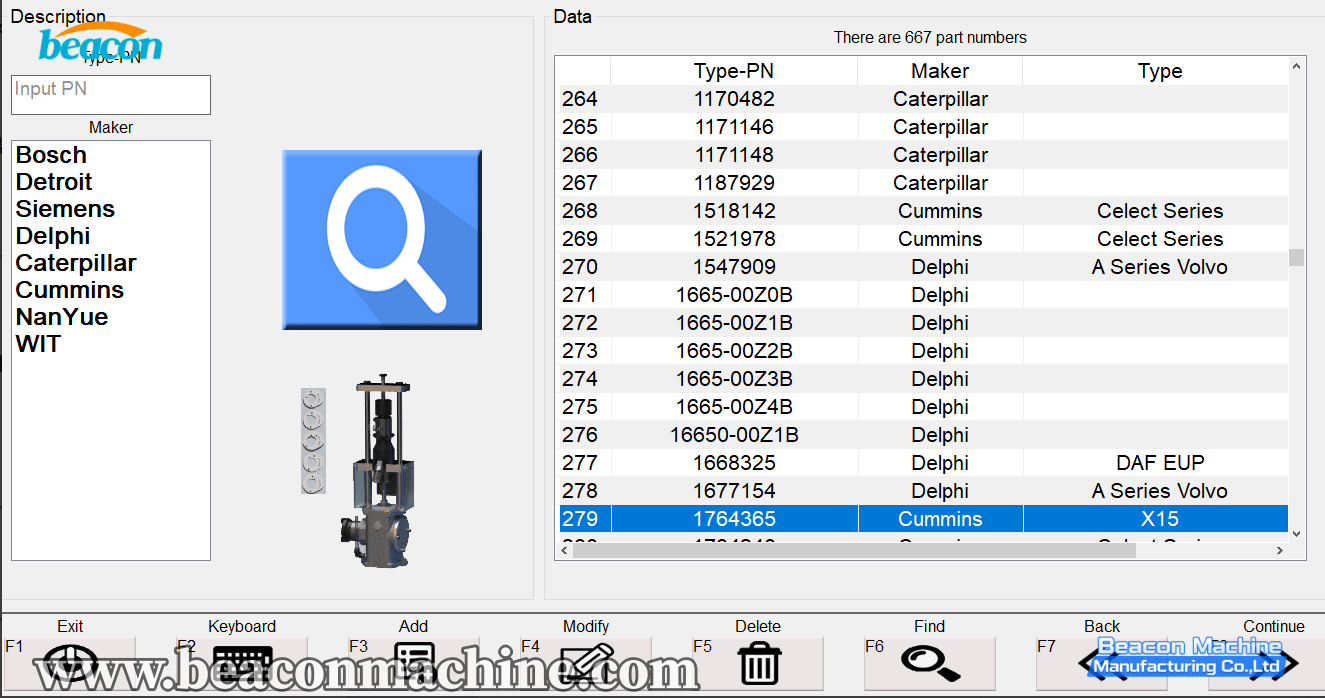

EUI/EUP: 667 test plans.

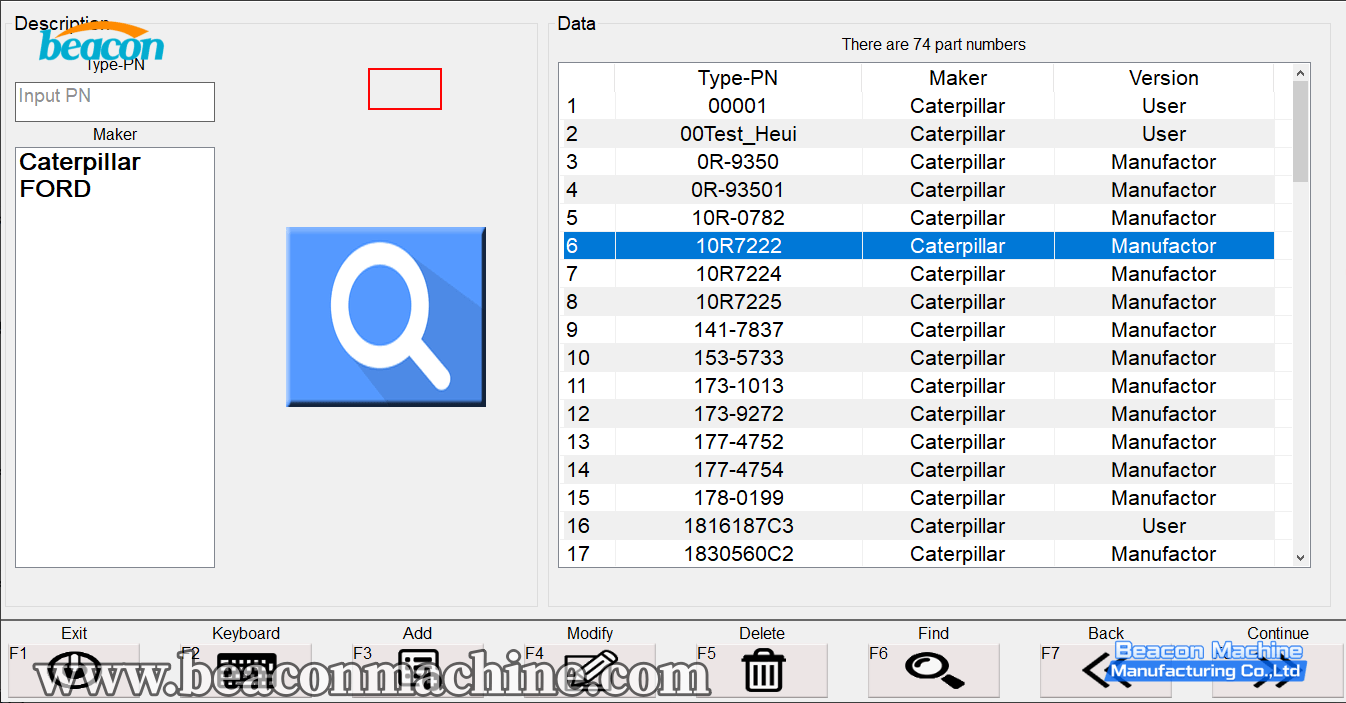

HEUI: 74 test plans.

4. Frequently Asked Questions (FAQ)

Here are the answers to the most common technical questions regarding the Beacon Machine system.

Data & Coverage

Q: How much data is included for special pumps like HP0 or CAT 320D?

Denso HP0: 83 test plans.

CAT 320D: 9 test plans.

ZME Metering Units: 42 test plans.

Cummins PT Injectors: 15 test plans.

Q: Can the system measure electrical parameters?

Yes. It is standard functionality. The system measures Resistance and Inductance for solenoid injectors. For Piezoelectric injectors, it automatically measures Capacitance.

Q: Does it support Cummins ISX injectors?

Yes. The database includes 54 XPI test plans and 12 X15 test plans.

Settings & Customization

Q: What is the default system password?

The factory passwords are 1357 or cr1357.

Note: Backend settings are calibrated before leaving the factory. If you must change them, please take a photo of the original data first.

Q: How many languages are supported?

The system supports 15 languages.

To Change: Go to Settings -> Select Language -> Restart System.

To Add a Language: Go to Settings -> Edit -> Select Add -> Edit Text -> Save.

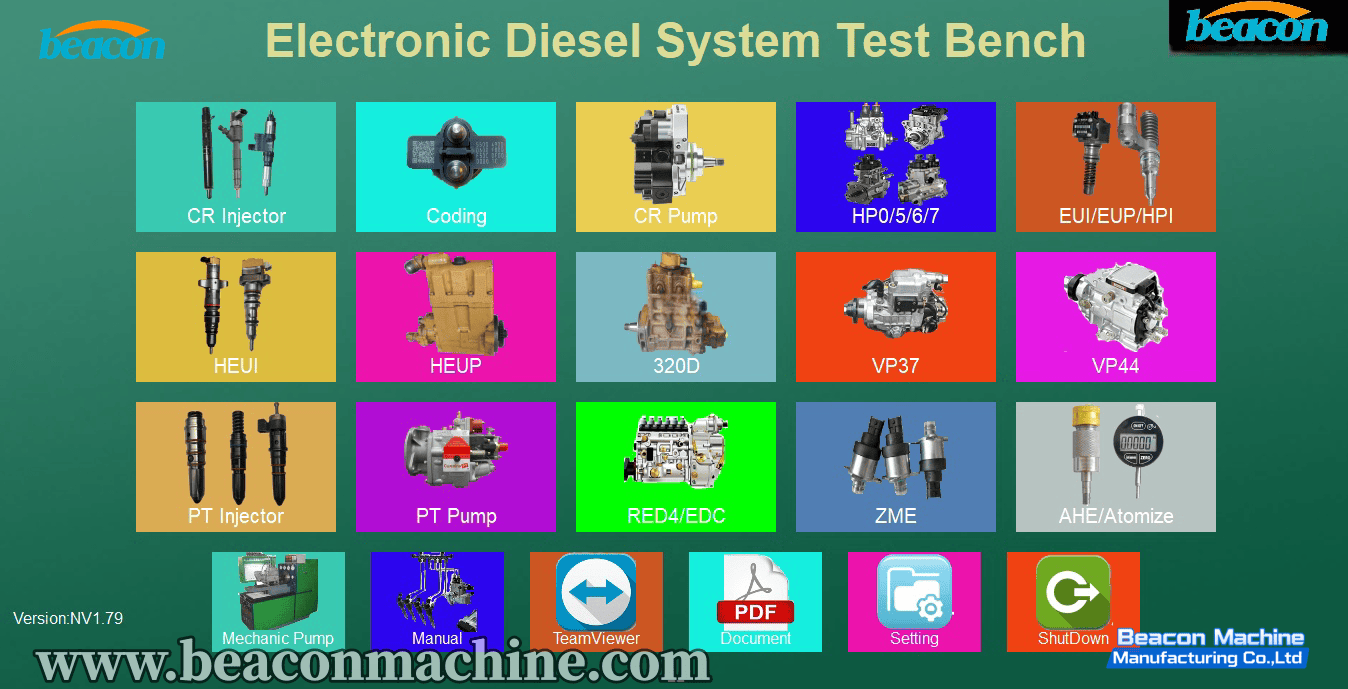

Q: Can I put my own company Logo on the software?

Yes. You can replace the "BEACON" logo with your own brand logo on both the software interface and the printed test reports.

Upgrades & Functions

Q: Can I add functions later if I don't buy them now?

Yes. Functions like Injector Coding, CP4 testing, ZME testing, or HEUI can be activated remotely. You do not need to ship the machine back; we can unlock the software modules over the internet.

Q: How do I keep the database up to date?

The system supports automatic network upgrades. As long as the machine is connected to the internet, you can download the latest test data and functions.

Related products

Language

Language